Clay Dryer

Clay Dryer Introduction

The clay dryer is mainly used for the drying of various types of clay mud such as bentonite, kaolin, aluminum, and iron clay.

This new clay dryer, developed by our company, utilizes advanced drying technology tailored to the unique properties of clay. Internal cleaning and crushing machine within the rotating drum prevent material buildup and ensure uniform drying. Key features of the clay dryer include extended operational lifespan, dependable performance, adaptable settings, and eco-friendly energy efficiency.

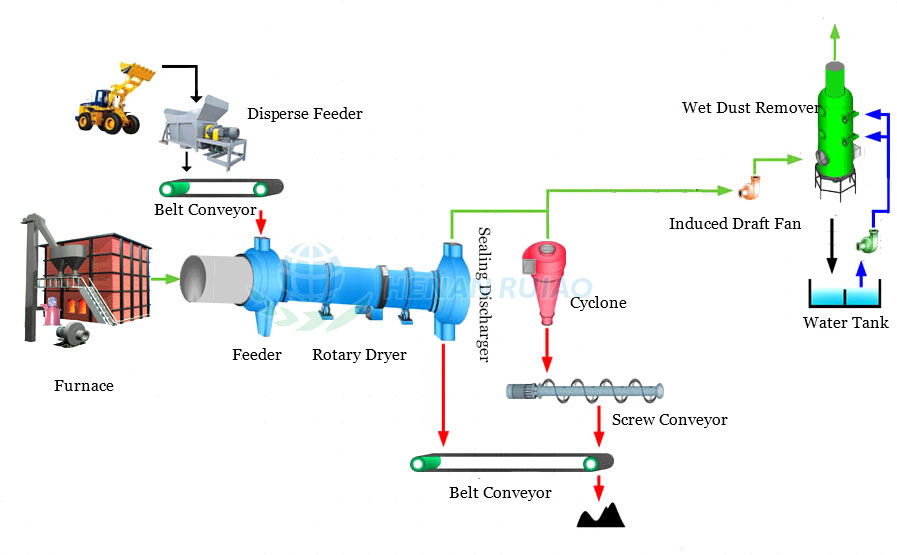

Clay Dryer System

Clay Dryer Advantages

1. The drying intensity is high. Since the material is highly dispersed in the air flow, the entire surface of the particles is actively the effective area for drying, and the drying time is short;

2. The air flow dryer has a simple structure, small footprint, and is easy to build and maintain;

3. Large processing capacity and high thermal efficiency. When drying unbound water, the thermal efficiency can reach more than 70%.

4. Compared with ordinary dryers on the market, this clay dryer has a high output, which is more than twice that of ordinary dryers;

5. There are no requirements for the working environment, and clay can be dried in harsh environments without affecting the drying effect and efficiency;

6. Made of high wear-resistant materials, it has strong wear resistance and pressure resistance, and has a longer service life;

7. The quality is excellent, the operation is smooth, the number of failures is very few, and the overall operating cost is reduced.

Technical Parameters

Model | Drum diameter | Drum | Capacity | Rotary Speed | Drum Inclination | Power | Weight |

Φ1.0×10 | Φ1000 | 10000 | 1-4 | 1.1-6 | 5 | 7.5 | 7.85 |

Φ1.2×12 | Φ1200 | 12000 | 3-7 | 1.2-6.5 | 5 | 11 | 13.3 |

Φ1.5×14 | Φ1500 | 14000 | 7-10 | 1.4-7 | 5 | 15 | 17.9 |

Φ1.6×14 | Φ1600 | 14000 | 8-11 | 1.4-7 | 5 | 15 | 18.6 |

Φ1.8×14 | Φ1800 | 14000 | 9-13 | 3.5-6.5 | 5 | 15 | 20.85 |

Φ2.4×18 | Φ2400 | 18000 | 21-31 | 2.2-7.4 | 4 | 30 | 45 |

Φ2.4×22 | Φ2400 | 22000 | 26-38 | 2.2-7.4 | 4 | 37 | 58 |

Φ2.6×20 | Φ2600 | 20000 | 28-40 | 2.2-7.4 | 4 | 45 | 60.5 |

Φ3.0×25 | Φ3000 | 25000 | 46-64 | 8.4-3.85 | 4 | 75 | 96 |

Φ3.2×25 | Φ3200 | 25000 | 60-80 | 2.4-7.6 | 4 | 90 | 119 |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386