Gypsum Dryer

Gypsum Dryer Introduction

Our gypsum dryer features an advanced control system enabling the operator to dry gypsum depending on the industry requirement. Our gypsum dryer can dry gypsum to a moisture content of less than 8% and control the particle size to less than 8 mm for use in the production of gypsum board, cement or briquette, etc.

And our Gypsum dryer is suitable for drying natural gypsum, FGD gypsum, phosphogypsum, sulfur gypsum, , gypsum slag, gypsum sludge and other gypsum materials. Thus, gypsum rotary dryer is widely used in construction plant, cement production, power plants, fertilizer production, pharmaceutical & food Industry and so on.

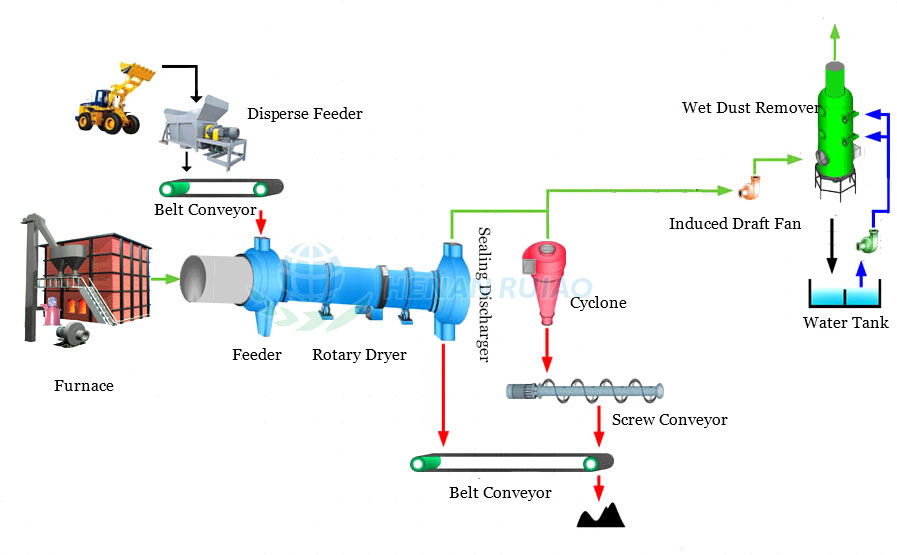

Gypsum Dryer System

The gypsum rotary dryer system is mainly composed of hot blast stove, belt feeder, rotary dryer, belt feeder, induced draft fan, cyclone dust collector, bag filter (or wet dust collector) and operation control system.

Why Choose Our Gypsum Dryer

1. Uniform drying

The rotating design of the drum dryer causes the gypsum to continuously tumble in the drum, ensuring the gypsum is heated evenly and achieving uniform drying;

2. Highly customization

Different drum guide plate structures and drying processes are designed according to different materials to meet the drying requirements of materials with different characteristics;

3. Adjustable drying parameters

it features a user-friendly control system that lets users control the speed of the drum, drying temperature, airflow, and various other drying parameters.

4. Fully automatically, labor and cost saving

Adopting an automatic control system, quantitative feeding, automatic heat source control, and mechanical sealing and packaging, the entire production process requires only one person to monitor in real time, saving labor and cost.

5. Various heating choices

Depending on users’ situation, the heating source can be coal, gas, diesel oil, biomass pellet, etc.

6. Environmental friendly

Multiple advanced dust removal are adopted to ensure that emissions of exhaust gas meet local environmental protection standards.

Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | ≤5 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | ≤5 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | ≤5 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | ≤5 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | ≤5 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | ≤5 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | ≤5 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | ≤5 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | ≤5 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386