Lignite Dryer

Lignite Dryer Introduction

The lignite (brown coal) dryer is specifically designed for high-moisture lignite (brown coal), adopting advanced hot air circulation technology to quickly and evenly reduce the moisture content lignite. It can reduce the moisture content of lignite from 35%-60% to 10%-20% or even lower, improving the combustion efficiency and calorific value of lignite. Additionally, this equipment is easy to operate and maintain, providing significant economic benefits for coal processing enterprises.

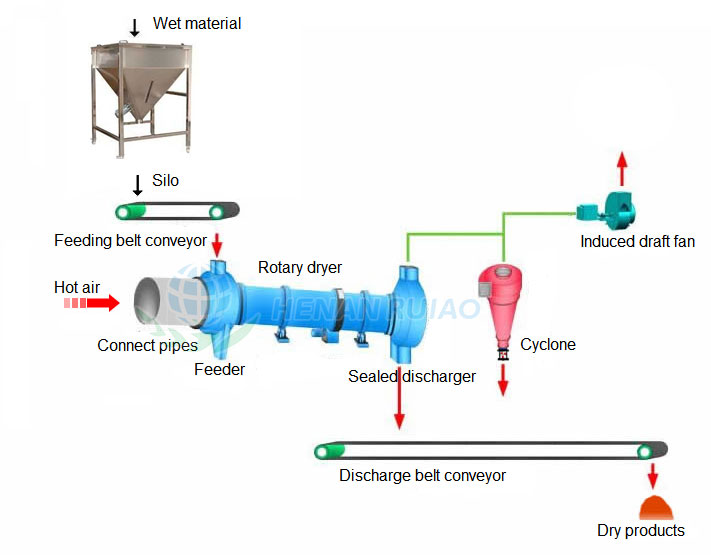

Lignite Dryer System

The lignite drying system mainly consists of a heat source, dispersed feeding, belt feeding machine, drum equipment, unloader, dust removal equipment, belt discharge machine, induced draft fan, and power distribution operation.

1.Raw material crushing and loading system (optional):

For raw materials that are too large, crushers will be needed to crush the lignite to meet the particle size requirements. In order to achieve fully drying of the lignite, the feed particle size is about 20-50mm.

2.Combustion heating system:

Use pulverized coal injection furnace, pulverized coal silo, air flow conveying and other equipment to ensure that a stable high-temperature heat medium is provided to the drying system.

3.Drying and dehydration system:

Use sealed feed box, anti-tempering chute, rotary drum dryer, discharge box and other equipment to complete the mass and heat exchange between high-moisture lignite and high-temperature hot air.

4. Environmental protection dust removal system (optional): Cyclone dust collector, explosion-proof bag dust collector, induced draft fan and other equipment are used to recover fine particles in the dried and achieve tail gas emission standards.

5. Power distribution and control system (optional):

PLC automatic control system, complete power distribution device, local box, video monitoring system and other electrical equipment are used to achieve the control and monitoring of the drying system.

6.Product conveying system:

Use belt conveyor to transport the dried products to the user’s designated location.

Lignite Dryer Working Principle

The lignite dryer consists of a rotary drum that is positioned horizontally, with one end slightly higher than the other. When the equipment operates, wet lignite is delivered to the feed hopper via a belt conveyor. The lignite enters the dryer from the higher end, and the dryer continuously rotates, causing the lignite to be lifted to the top and then fall down.

The inner wall of the drum is equipped with lifting plates designed to evenly distribute the lignite at higher points, increasing the contact area between the lignite and the air.

Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | 13±2 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | 13±2 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | 13±2 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | 13±2 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | 13±2 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | 13±2 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | 13±2 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | 13±2 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | 13±2 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386